Laser scanner uses JVL MAC Motors

|

DHI delivers large scanner that utilises JVL equipment

Located in the town of Hørsholm north of Copenhagen, the DHI Group has recently completed development of a new large scanner for investigating the effects of the sea on installations such as harbours and ports.

DHI is an independent, international consulting and research organisation that operates in fields such as water and marine environment, chemical management, industrial environment, water and marine resources, coastal and marine engineering, hydraulic structures, as well as hydrodynamics and related areas.

In coastal and marine engineering, DHI’s expertise is heavily involved in numeric modelling and hydraulic test facilities for testing harbour installations under various wave conditions. The test waves are created by large, built-in wave generating systems for which JVL has previously supplied motors.

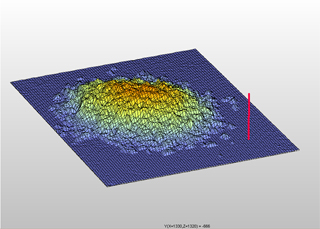

To measure the effects of the waves on model installations, a large scanner is used. This scanner can be moved over the entire test basin. Using software developed by the University of Aalborg, 3-dimensional plots of the model installation can be made before and after the effects of waves. The scanner can also be used to map the contour of the model seabed.

The recently developed scanner moves on a carriage along a 12-meter long lattice girder which itself moves on rails to cover the entire 18 meter length of the test basin. The entire scanner installation weighs approximately 300 kg.

Movement of the scanner assembly on the lattice girder utilizes a JVL MAC141 integrated servo motor with RS232/485 and Pulse Direction module MAC00-B4. On the carriage itself, the scanner probe is moved up and down using a second MAC141 equipped with a Nano PLC module MAC00-R4. This motor is further equipped with brake MAB23 to maintain the probe in the required vertical position. Both motors use HTRG planetary gears, with gear ratios of 100:1 on the one and 40:1 on the other.

The forward and reverse movement of the lattice girder on rails is performed by MAC141 motors at each end that also use HTRG planetary gears. A gear ratio of 400:1 is used. The entire system is controlled via an RS232 bus.

The scanner has been delivered to a hydraulic institute in Hanoi, Vietnam.

DHI opted for JVL’s MAC motors because of their compact construction and the simple implementation of the entire control system provided by the MAC motors.

More information about:

MAC 141 motors  One of the MAC motors and gears used to move the lattice girder assembly |

|

The assembled scanner in the test lab (without water)

Scanner carriage with motors, brake and gears

Stone aggregate pile

Plot of the aggregate pile |

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk