Grundfos using JVL Turntable

|

Pump impellers assembled on JVL turntable controlled by JVL and Yaskawa controllers

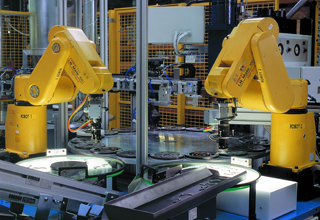

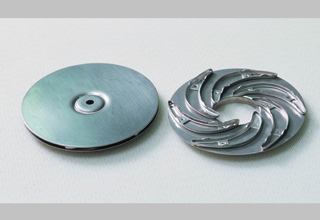

Grundfos Tools & Machines, which is a division of the company's Technology Centre, is completing construction of a large turntable machine that assembles impellers for the Grundfos series of CR1, CR2 and CR3 pump chambers. The assembly machine will be used by the CR plant in the manufacture of centrifugal pumps. The impellers consist of 2 cylindrical stainless steel discs, between which 6 impeller blades are mounted. The first 3 impeller blades are positioned by a Fanuc robot in fixtures which also function as electrodes for the welding process. At the turntable's next position, the remaining 3 impeller blades are positioned by a second robot. At the next position, an impeller disc is placed onto the 6 impeller blades, and at the next stage the blades are welded onto the disc. The unit is then moved to a second turntable where the second disc is mounted and welded, completing assembly of the impeller. To ensure that components are mounted with the correct side up on the turntable and to tell the robots their position, vision systems are used. The Turntable is driven by a Yaskawa SGDH-20 (2kW) servo driver and an SGMGH (2kW) servo motor via a Spinea TS240 gear with a ratio of 87:1. The driver is controlled from an SMI30 Indexer, which has the total of 3x6 positions stored in its registers. The Indexer operates in JVL's specially-developed turntable mode, which ensures that no follow errors occur, i.e. the turntable always achieves precise positioning. JVL undertook the programming of the Indexer in co-operation with the Grundfos Tools & Machine division. Overall control of the entire assembly machine is performed by an Allen-Bradley PLC. At JVL, we have been particularly pleased to take part in the solution of this exciting application. |

|

The Turntable assembly machine with the two Fanuc robots

Yaskawa driver and JVL Indexer in the control cabinet

The pump impeller with and without the second of the two discs |

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk