Save Costs with JVL's Integrated Stepper Motors featuring IO-Link

PRESS release: March 2025

Birkerød, Denmark - JVL A/S, a leader in the fields of integrated servo and stepper motors for factory automation, is proud to announce the launch of its latest innovation: the Integrated Stepper motor with IO-Link. This groundbreaking product is set to transform factory automation by offering a cost-effective alternative to traditional Ethernet-based systems while simplifying integration with Siemens and Rockwell PLCs.

Overall, IO-Link is a transformative technology that brings intelligence and efficiency to the factory floor, making it a cornerstone of modern industrial automation to a much lower cost than Industrial Ethernet.

IO-Link is becoming increasingly popular and enables bi-directional communication between sensors/actuators/motors and PLC control systems, allowing for real-time data exchange and diagnostics.

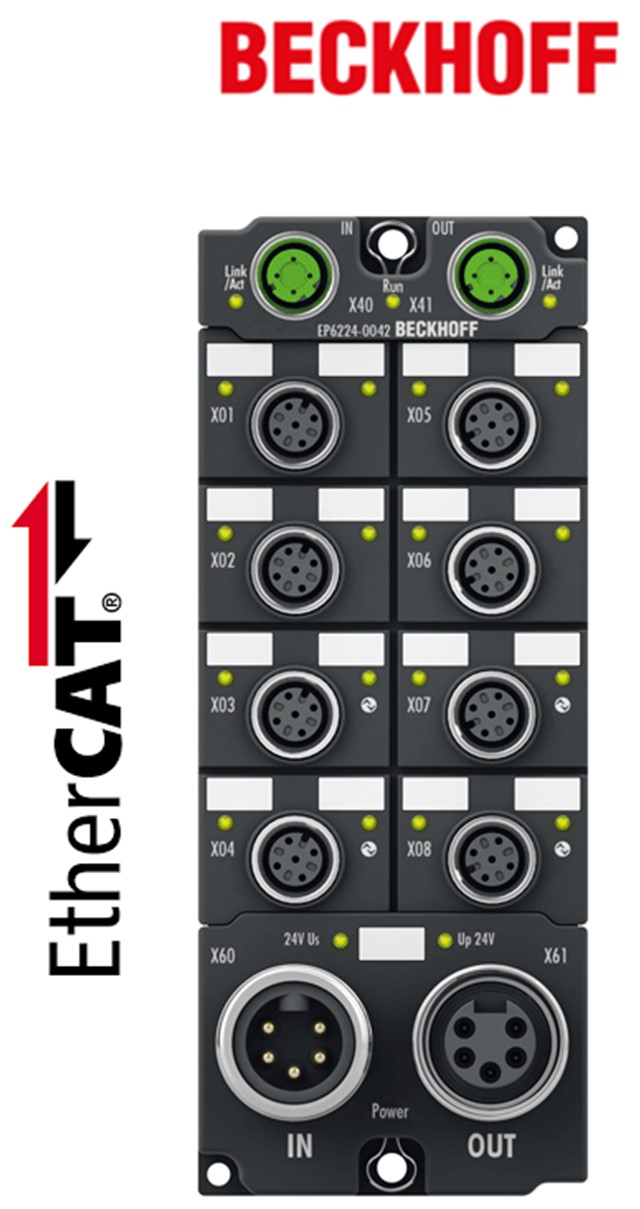

JVL’s IO-Link can be used on any platforms. Balluff, Baumer and other companies deliver high quality IO-Link masters that work flawless with Rockwell, Siemens and Beckhoff PLCs.

IO-Link is becoming increasingly popular and enables bi-directional communication between sensors/actuators/motors and PLC control systems, allowing for real-time data exchange and diagnostics.

JVL’s IO-Link can be used on any platforms. Balluff, Baumer and other companies deliver high quality IO-Link masters that work flawless with Rockwell, Siemens and Beckhoff PLCs.

Save Cost – IO-Link vs Ethernet

Both IO-Link and Industrial Ethernet have their strengths and weaknesses, and the choice between them depends on the specific needs and constraints of your automation project. Save between 10-15% in the investment costs when integrating JVL motors by using IO-Link instead of traditional Ethernet-based control networks.

Fastest IO-Link on the market today

JVL delivers the fastest IO-Link available today. While Ethernet is often perceived as a higher-speed bus, JVL's IO-Link can achieve a 2-byte response time of less than 1 ms, closely matching Ethernet's performance. For larger data transfers and multiple registers, IO-Link's response time ranges from 20-30 ms, which is slower than Ethernet but sufficient for most applications.

IO-Link cycle times as low as 1 ms is achieved using the ultra compact Mode FM. The default configuration supports cycle times as low as 5 ms on the IO-Link channel.

IO-Link cycle times as low as 1 ms is achieved using the ultra compact Mode FM. The default configuration supports cycle times as low as 5 ms on the IO-Link channel.

Comprehensive Motion Control

Even though the IO-Link based JVL control never was intended to be used in hard timing restrained applications, very short reaction time can be achieved. All normal motion functions can be controlled through the IO-Link channel.

Rockwell or Siemens users will be able to have a motor spinning in 2 minutes by using JVL developed add on instructions and function blocks that are freely available from jvl.dk.

Rockwell or Siemens users will be able to have a motor spinning in 2 minutes by using JVL developed add on instructions and function blocks that are freely available from jvl.dk.

Built-in IO-Link

The JVL IO-Link is integrated directly into the motor, eliminating the need for a gateway that could slow down overall speed. Developed by JVL, the IO-Link protocol is embedded in the main microprocessor, optimized for the best possible response time, and ready for future enhancements or customer-specific requirements.

JVL’s IO-Link features

- AOIs and FBs (function blocks) available for Rockwell and Siemens PLC

- IODD files for plug and play simplified Integration with PLC

- Support Data storage, Event handling, Diagnostic and Block parameter

- Any IO-Link master will be able to control the motor

- All motion functions can be controlled through the IO-Link channel

- All motor registers can be read or written

- Mode FM ultra compact processdata format with 2 byte for extremely low IO-Link cycletime <1mS

- Single cable with Power over IO-Link cable for low power and battery applications

- Minimize stock Model with IO-Link and Ethernet in same motor

- Easy commissioning using IODD files and Parameterization directly from the IO-Link master

- Mode 66 for 6 in and 6 out registers similar to the well-known JVL Ethernet concept

- Mode 88 for 8 in and 8 out 100% user configurable register setup, similar to the well-known JVL Ethernet concept

- Conformance tool tested and passed

- IO-Link standard 1.1.4 supported

- Specialized Gripper mode Simple control with high servo-controlled accuracy

Conformance approved functionality

- Data storage for easy commissioning and replacement. Mount new motor and parameterization is done automatically from the PLC

- Event Handling: Detection and reporting of specific events or conditions.

- Notifications: Informational updates about the device status

- Warnings: Indications of potential issues that could affect device performance like motor temperature too high

- Errors: Critical conditions that require immediate attention like motor overload

- Diagnostic Data: Real-time information about the status and performance of IO-Link motors. It helps in identifying issues such as device malfunctions, communication errors, or parameter deviations

- Block parameter in an IO-Link master is used for efficient data exchange between the master and connected IO-Link motors. It allows for the grouping of multiple parameters into a single block, which can be read or written in one operation. This helps to reduce communication overhead and improve performance when configuring or monitoring multiple parameters simultaneously

Typical applications

- Format adjustment: Replacement of handwheel adjustment

- Gripper with high precision and dynamics using the JVL ServoStep™ control system

- Pick-and-place operations: Move between 2..8 pre-selected positions with pre-configured velocity, acceleration and torque settings

- Air-cylinder replacement with precise acceleration and speed control

- Setup axis only requiring a minimal bandwidth and no hard timing or synchronization requirement

Robust and Reliable Communications

IO-Link is a 24V serial bidirectional bus that uses 230 kbit communication, offering high noise immunity and eliminating the need for shielded cables. The IO-Link connector built into the motor is an M12 5-pin with optional Power over IO-Link for motors below 3A, such as the JVL integrated stepper MIS17 or small MIS23 motors. Industrial Ethernet and IO-Link both in the same motors are also available.

IO-Link is a 24V serial bidirectional bus that uses 230 kbit communication, offering high noise immunity and eliminating the need for shielded cables. The IO-Link connector built into the motor is an M12 5-pin with optional Power over IO-Link for motors below 3A, such as the JVL integrated stepper MIS17 or small MIS23 motors. Industrial Ethernet and IO-Link both in the same motors are also available.

Quote from our CEO:

"We are thrilled to introduce our integrated stepper motors with IO-Link to the market. This product represents a significant advancement in factory automation, offering a cost-effective and highly efficient solution for our customers. By simplifying the integration process with leading PLCs like Siemens and Rockwell, we are enabling manufacturers to achieve greater productivity and operational excellence,"

- Mads Vernon Jørgensen CEO of JVL A/S.

- Mads Vernon Jørgensen CEO of JVL A/S.

All-in-one unit

ServoStep™ has everything built-in including motor, encoder, drive electronics, control electronics with ePLC™ and optional Ethernet or CAN bus integrated into one compact unit. All major industrial Ethernet protocols like Profinet, EtherNet/IP, EtherCAT, SERCOS, ModbusTCP/UDP and Powerlink are available. Options include absolute multiturn encoders and STO (safe torque off, SIL3). Also included are 8 I/O points which can be individually configured as digital input or output – or analogue input. The IOs can be used as local/remote IOs for the central PLC – or used together with the ePLC™ in stand-alone applications.

ServoStep™ has everything built-in including motor, encoder, drive electronics, control electronics with ePLC™ and optional Ethernet or CAN bus integrated into one compact unit. All major industrial Ethernet protocols like Profinet, EtherNet/IP, EtherCAT, SERCOS, ModbusTCP/UDP and Powerlink are available. Options include absolute multiturn encoders and STO (safe torque off, SIL3). Also included are 8 I/O points which can be individually configured as digital input or output – or analogue input. The IOs can be used as local/remote IOs for the central PLC – or used together with the ePLC™ in stand-alone applications.

Read more about JVL´s Built-in IO-Link solution: IO-Link

Read more about JVL´s Integrated Stepper Motors here: MIS - Integrated Stepper Motor

Read more about JVL´s Integrated Servo Motors here: MAC - Integrated Servo Motor

Read more about JVL´s Integrated Stepper Motors - Linear actuators here: MIL - Integrated Stepper Motor Linear Actuator

For further information, please contact:

JVL A/S, Bregnerødvej 127, 3460 Birkerød, Denmark.

Tel. +45 4582 4440. E-mail: jvl@jvl.dk. Web:

www.jvl.dk

About JVL - JVL is a world leader within the development and production of efficient and compact integrated servo motors and integrated stepper motors. MAC motor® are a series of integrated brushless servo motors (up to 4500 W and 12 kW peak) and ServoStep™ are a series of integrated stepper motors (up to 25 Nm). Both motor series include motor, encoder, drive electronics, control electronics with ePLC™ and optional Ethernet integrated into one compact unit. All major industrial Ethernet protocols like Profinet, EtherNet/IP, EtherCAT, SERCOS, ModbusTCP/UDP and Powerlink are available.

Options include: absolute multiturn encoders, STO (safe torque off, SIL3) and brakes.

JVL has more than 30 years of motion control experience and are well known for their development and production of highly specialized integrated motors with industrial Ethernet and customized improvements. The close co-operation with customers and representatives results in cost-effective and technical optimized solutions for both basic and advanced motion control applications.

JVL's wide selection of quality products for motion control applications include: Integrated brushless servo motors, integrated stepper motors, AC servo motor controllers, motor drivers (DC, AC and steppers), brakes, gearboxes, hollow rotary actuators and HMI touch panels.

Options include: absolute multiturn encoders, STO (safe torque off, SIL3) and brakes.

JVL has more than 30 years of motion control experience and are well known for their development and production of highly specialized integrated motors with industrial Ethernet and customized improvements. The close co-operation with customers and representatives results in cost-effective and technical optimized solutions for both basic and advanced motion control applications.

JVL's wide selection of quality products for motion control applications include: Integrated brushless servo motors, integrated stepper motors, AC servo motor controllers, motor drivers (DC, AC and steppers), brakes, gearboxes, hollow rotary actuators and HMI touch panels.

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk