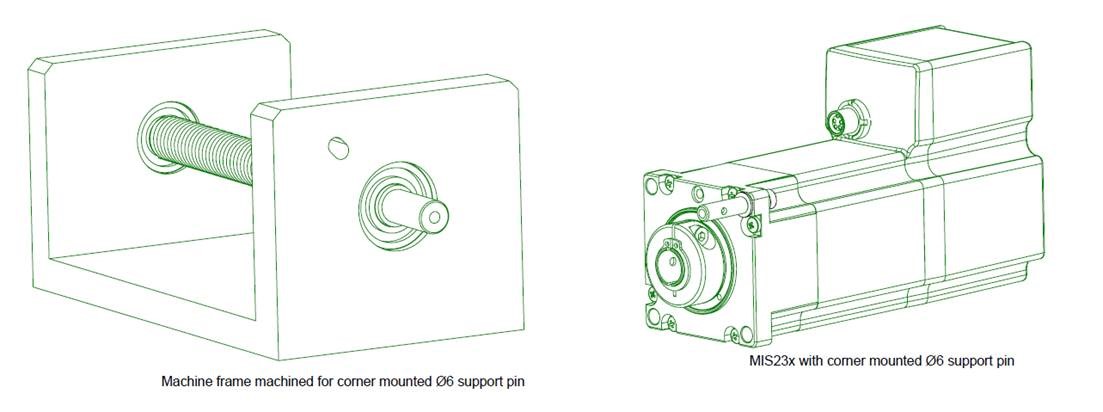

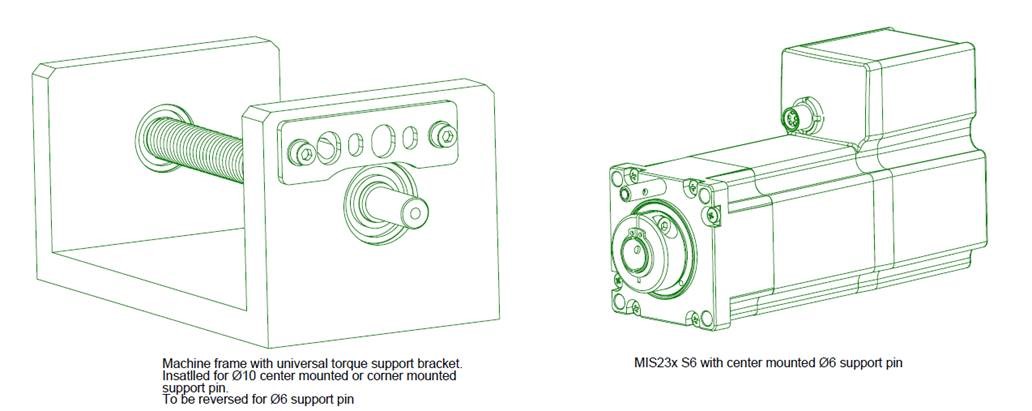

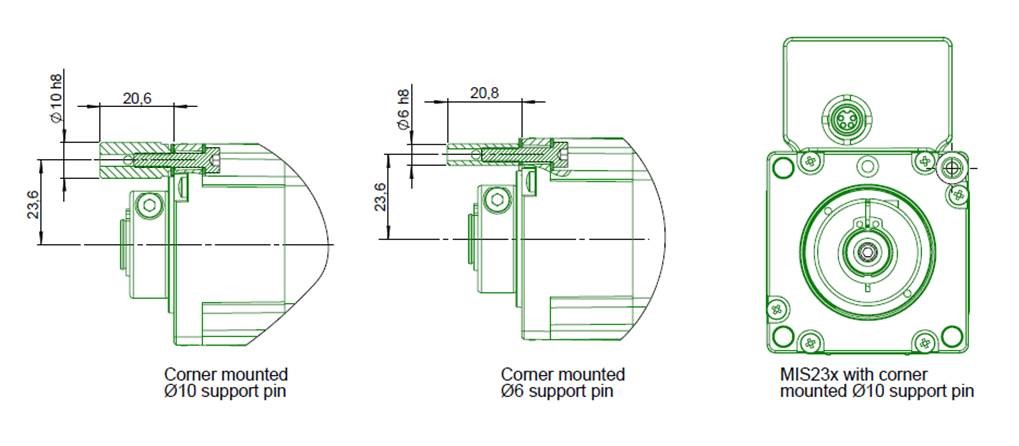

Installing MIS23x motors with self-supporting shaft or spindle

A motor directly connected to a shaft or spindle that is already supported by two bearings in a machine frame (self-supported) must have a torque support to prevent the motor body from rotating.

Because of slight imperfections motor and shaft may not be perfectly aligned causing the motor to perform a wiggling movement. This is not an indication of a defective motor and it does not influence the function.

The motor must be allowed to move freely or premature wear of bearings or other failure may result.

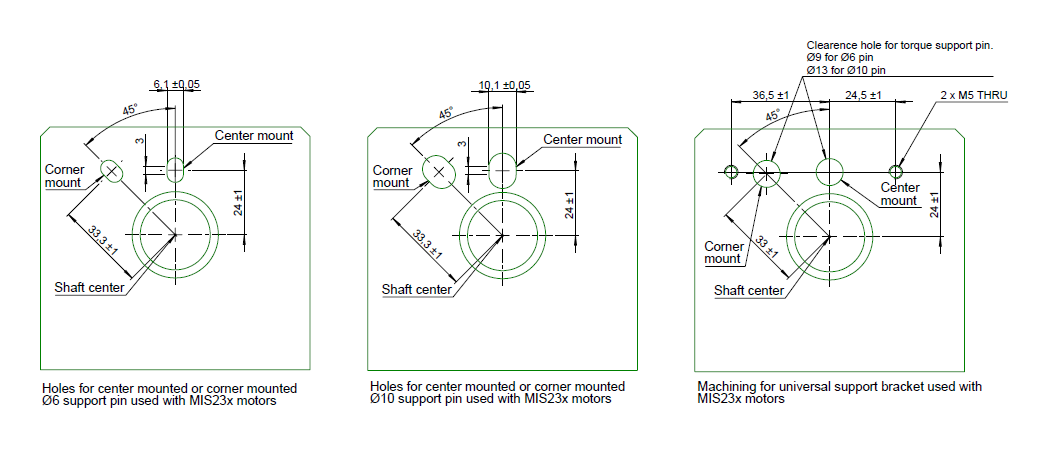

A hole in the machine frame for the torque support pin should have an oblong shape and a width 0.05 to 0.15 mm larger than the diameter of the support pin. Any surplus play influences the positioning accuracy.

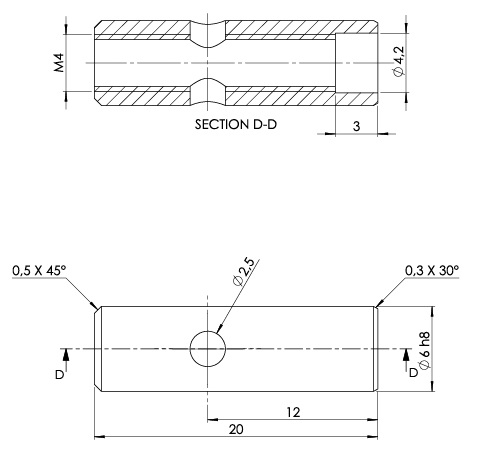

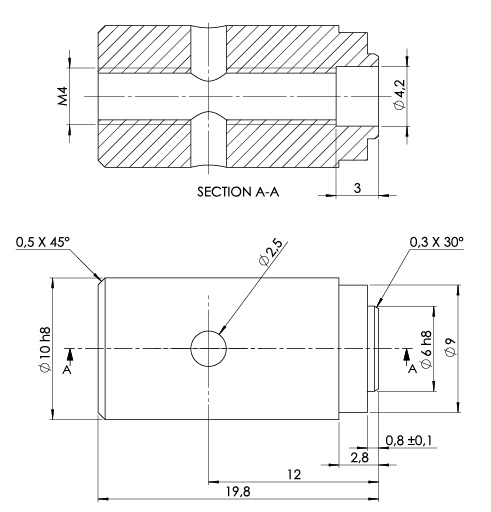

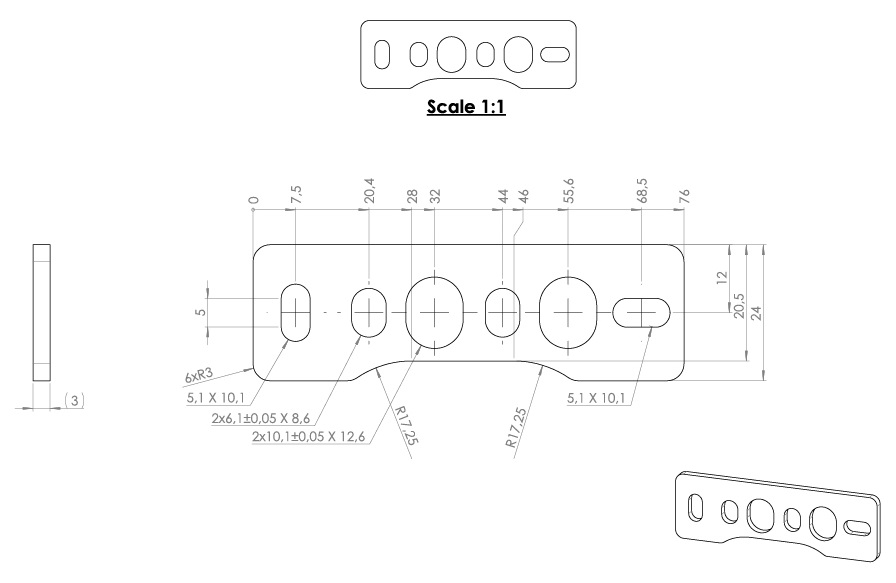

A torque support bracket for fitting to the machine frame is available from JVL. The bracket has holes with appropriate fit and shape to match Ø6 and Ø10 support pins that are also available from JVL. Using the bracket eliminates the need of very precise machining of the machine frame which may be useful in situations where the motor is fitted to an existing machine.

Below is a list with torque support and bracket for MIS motor

| MM4602 |

6 mm Torque support for MIS23 |

|

| MM4601 |

10 mm Torque support for MIS23 |

|

| MM4604 |

Torque support bracket |

|

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk