Understanding the Differences between Cat 5e and Cat 6 Ethernet Cabling

While there are three Ethernet cable choices in use—Cat 5, Cat 5e and Cat 6—only the latter two are still considered viable choices for telecom and industrial applications. Since August 2009, when ANSI/TIA-568-C.2 (Balanced Twisted-Pair Telecommunications Cabling and Components Standard) was published, category 5 has been superseded by category 5e and is no longer recognized by this standard. The use of category 5e or better cabling is recommended for all new installations. And yet even with this simplification, there is still a great deal of confusion among Ethernet cable users concerning whether to use Cat 5e or Cat 6 cable.

Cat 5e cabling requirements were first published in 2000 to address the additional transmission performance characterization required by applications such as 1000BASE-T that use bidirectional and full four-pair transmission schemes. The 568 standard added performance headroom to Cat 5 performance limits and characterized several new transmission criteria that were required to support Gigabit Ethernet over a worst case four-connector channel.

Cat 6 cabling delivers double the signal-to-noise margin of Cat 5e cabling and provides the performance headroom desired by end-users to ensure that their cabling plant can withstand the rigors of the cabling environment and still support 1000BASE-T when it comes time for an application upgrade. The Cat 6 cabling specification development process also brought to light the need to limit the conversion of differential mode signals to common mode signals and vice versa through the characterization of component balance, resulting in cabling systems with improved electromagnetic compatibility (EMC) performance.

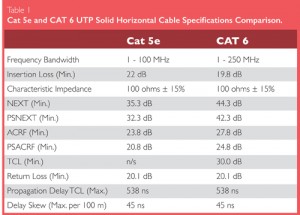

The TIA (Telecommunications Industry Association) is the leader in the development of structured cabling standards. By comparing the requirements in the TIA standard, one can easily see the differences between the electrical performance requirements of Cat 5e and Cat 6 cables. Table 1 provides comparative horizontal cable performance data for category 5e and category 6, using a UTP cable as an example. Frequency-dependent values are given for 100 MHz.

| Generally speaking, Cat 6 cable has wider frequency bandwidth and tighter requirements on electrical performance. Although the signal transmission speed and skew of delay on all pairs are the same, Cat 6 cable can still deliver more data and keep better signal integrity due to the bandwidth and headroom. |

| To ensure the cable is Cat 6 compliant, cable manufacturers may use a slightly larger conductor to meet the insertion loss requirement and higher grade of insulation material to meet the impedance and propagation delay requirements. (Insulation material selection also depends on UL flame ratings; for example, using polypropylene or polyethylene for riser-rated cable and FEP for plenum-rated cable). Besides the raw material, cable construction also plays an important role in Cat 6 cable design. Various shorter pair lay lengths usually give better crosstalk performance. To further eliminate the crosstalk, a web or other shape of filler may be applied to separate the pairs from touching each other. The cable jacket and shield (for screened cable only) protect the cable core and keep the structure stable. |  |

On the other hand, well established and qualified manufacturing processese will ensure the cable is balanced, thus helping with other electrical parameters such as return loss, TCL and ELTCTL for Cat 6 cables.

Ethernet Cable for Industrial Use

If the cable is designed for an industrial environment, other factors should be considered as well. Cables used in industrial environments must be designed to work in harsh environments— temperature extremes, humidity and moisture, dust and mud, oil and solvents, corrosive chemicals, mechanical vibration, EMI interference, etc. Typical applications include oil, gas and petrochemical plants, water and wastewater facilities, wind farms, and mining. To make an Ethernet cable suitable for industrial environments, cable manufacturers use premium-grade insulation and jacket materials to meet higher temperature ratings and to withstand mechanical and environmental abuse. Besides the material changes, other components such as strength member and braid can also be used to help improve robustness and performance.

If the cable is designed for an industrial environment, other factors should be considered as well. Cables used in industrial environments must be designed to work in harsh environments— temperature extremes, humidity and moisture, dust and mud, oil and solvents, corrosive chemicals, mechanical vibration, EMI interference, etc. Typical applications include oil, gas and petrochemical plants, water and wastewater facilities, wind farms, and mining. To make an Ethernet cable suitable for industrial environments, cable manufacturers use premium-grade insulation and jacket materials to meet higher temperature ratings and to withstand mechanical and environmental abuse. Besides the material changes, other components such as strength member and braid can also be used to help improve robustness and performance.

| As for selecting the right cable for customer applications, use Table 2 as a starting point, then consider other factors such as cost and future expansion plan of the existing network. Table 2 summarizes cabling types capable of supporting commonly specified applications over 100-meter, four-connector topologies.It should be mentioned that many currently available Cat 5e cables of good quality can run near or at gigabit speeds, but they just cannot be "certified” for this use. On the other hand, Cat 6 is designed especially for gigabit use, and is certified to operate at said speed. |  |

A good review of the engineering specification (bandwidth, speed, existing hardware, etc.), as well as non-engineering considerations (cost, future expansion need, etc.) will help users make informed Ethernet cable purchase and installation decisions.

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk