Closed-Loop Integrated Stepper Motors in size NEMA17/23/34

PRESS release: April 2016.

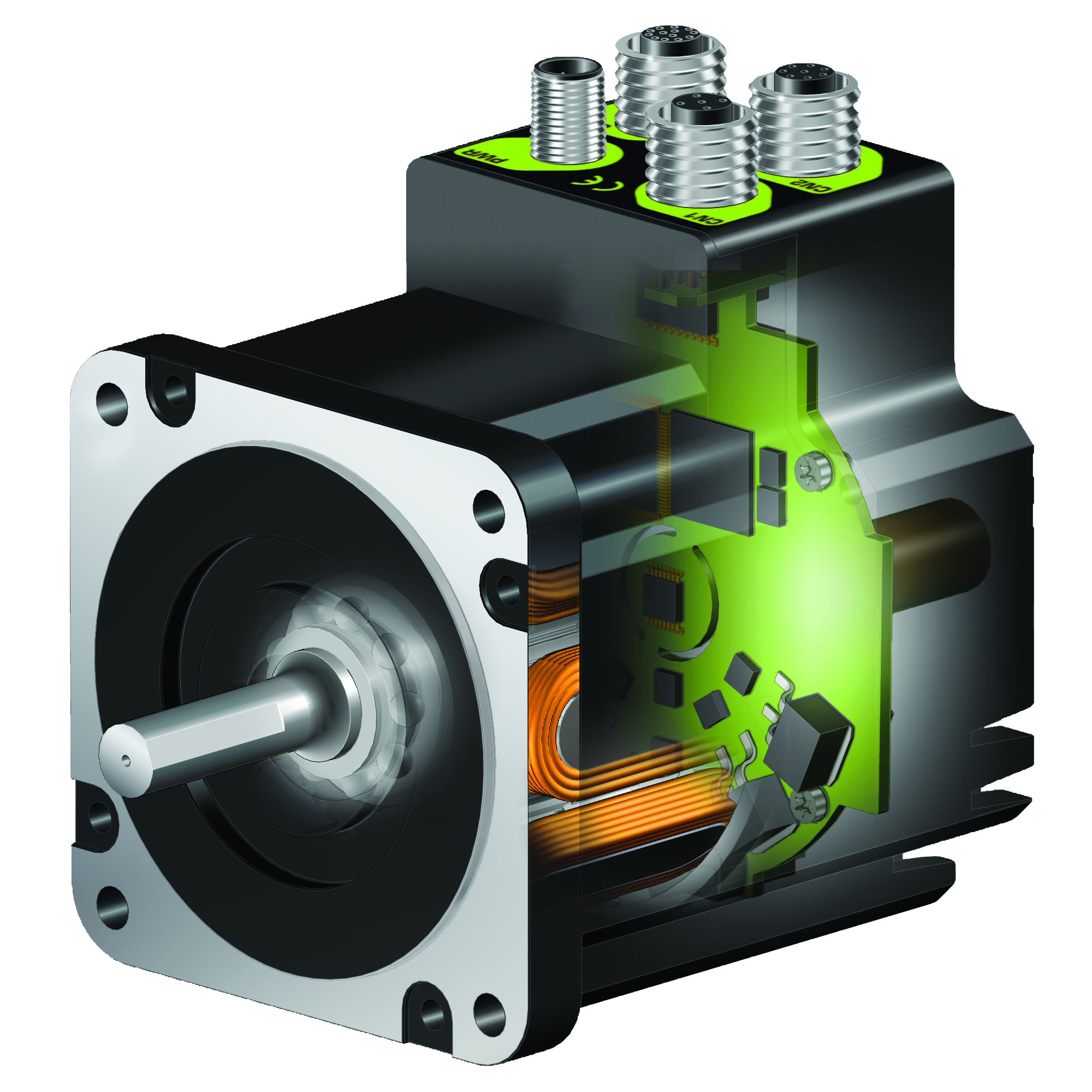

Birkerød, Denmark - JVL presents a new innovative closed-loop stepper motor technology for its NEMA17/23/34/43 integrated stepper motor range from 0.18 to 25 Nm. JVL, the European leader in the development of integrated servo and stepper motor technology, has now again developed a new and unique product in the field of integrated motor control.

New Innovative Technology

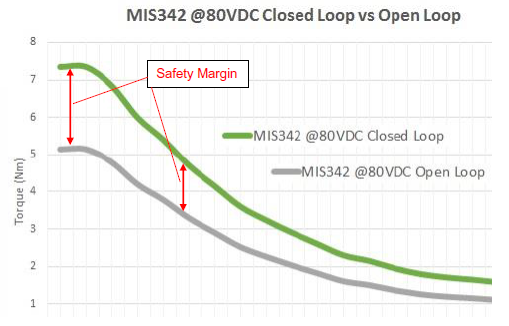

JVL closed-loop integrated stepper motors, ServoStep™, provide higher torque, faster acceleration, torque control, stall free operation and quieter movements than traditional step motor systems. ServoStep™ do this with greater efficiency and less motor heating because motor phase current are regulated up and down according to need. Performance of JVL closed-loop steppers are similar to servo motors, but with higher torque and often without need of gearbox, resulting in a more inexpensive solution. Design safety factors have always been high for stepper motors to ensure stall-free operation – now with ServoStep™ closed-loop control design can be very close to the limit resulting in even lower costs. ServoStep™ is a true closed-loop control system that compensates step angle errors during a movement and correct errors within a full step. If load becomes too high speed is lowered and position errors will always stay within two full-steps. Smart digital design and very high update rates (36 MHz) means there is no need of any manual adjustment or setup. It works like a perfect stepper motor benefitting from the servo motor technology.

| 100% Automatic Setup | No need to adjust any parameters. JVL closed-loop stepper motors always work fast and efficient to adapt motor to application. Extremely high update frequency: 36 MHz (where other suppliers have down to only 1 Hz update time). Calculations are made in FPGA and not in slow microprocessors. |

| Energy Saving | Like servo motors ServoStep™ always runs at lowest possible current. This reduces the need for cooling and results in a more "green” solution. |

| Stall-Free Operation And No Losing Of Steps | By always monitoring the actual rotor position, the control algorithm ensures that the motor does not lose any steps and it cannot stall. If the rotor is blocked mechanically it just continues right away when the obstruction is removed. |

| Torque Control Mode | The torque can be adjusted "on the fly” by the user or by the motor’s embedded PLC program. Applications that were previously impossible for a stepper motor can now be achieved. |

| Higher Acceleration & Speed | Stall-free operation means you do not need to worry about setting the motor to a very high acceleration ramp. The motor simply moves the load with the highest possible acceleration at any given time. The result is a much faster machine with more cycles per day. |

| Factory Loaded Linearization | The motor and encoder are calibrated during factory production in order to reach a very high mechanical precision. |

| Older Motors Are Supported | The Closed-loop control mode is backward compatible with older motors equipped with H2-type encoders. By updating the firmware, the user’s application can benefit from the stall-free operation with very high accelerations and lower power consumption. |

| Full Torque Available | The motor is capable of using the full torque according to the torque-velocity curve and therefore the need to have a safety overhead when dimensioning the machine is much less. Smaller motor = lower costs. |

Advantages compared to open loop stepper motors

- Position feedback and control

- Fast and easy commissioning. No tuning needed

- No stalling. No step losses at all

- Torque control

- Much faster positioning and more cycles per second

- Increased efficiency and thereby much lower temperature

- Shorter settling time

- Controls higher inertias than open loop steppers

- Higher load tolerance

- More quiet operation (lower acoustic noise)

- Longer lifetime due to lower temperature

- Correct positioning without overshoot and oscillation

Advantages compared to servo motors

- Very high Torque at low speed. Often 3-4 times higher in same motor flange size

- Very high ratio-of-inertia, often up to 40:1

- Faster commissioning. No tuning needed

- Lower price. Same price as open loop steppers

- Totally stiff at standstill. Full holding torque

- Direct drive without gearbox (better and more precise torque control)

- Correct positioning without overshoot

- No oscillation

- Very short settling time

Benefit in these application from closed-loop stepper motors

- Multiple axis applications (RS485, CANopen)

- Industrial Ethernet: Profinet, EtherNet/IP, EtherCAT, Powerlink, Modbus TCP, SERCOS III

- Positioning tasks with load changes

- Winding applications

- Belt drives (start/stop, positioning)

- Dosing pumps and filler systems

- Semi-conductor mounting

- Wafer production

- Textile machines and industrial sewing machines

- Robotics

- Testing and inspection systems

- Applications that require quiet operation, short settling times and precision positioning

| MIS34x Rotating torque control. |

MIS34x Linear moving control. |

|

|

|

|

|

| Webinar Closed-loop |

Torque homing |

|

|

|

|

|

| MIS motor tuning |

|

|

About JVL- JVL is a world leader within the development and production of efficient and compact integrated servo motors and integrated stepper motors. MAC motor® are a series of integrated brushless servo motors (up to 4500 W and 13.5 kW peak) and ServoStep™ are a series of integrated stepper motors (up to 25 Nm). Both the servo motor and stepper motor series includes the controller, Nano-PLC, encoder and bus system integrated into one compact unit. All industrial Ethernet protocols like Profinet, EtherCAT, EtherNet/IP, ModbusTCP and Powerlink are available.

JVL has more than 25 years of motion control experience and are well-known for their development and production of highly specialized integrated motors with industrial Ethernet and customized improvements. The close co-operation with customers and representatives result in cost-effective and technical optimized solutions for both basic and advanced motion control applications.

JVL's wide selection of quality products for motion control applications include: Integrated brushless Servo motors, Integrated Stepper motors, AC Servo motor controllers, Motor drivers (DC, AC and Steppers), Brakes, Gear boxes and HMI touch panels.

For further information, please contact:

JVL Industri Elektronik A/S, Bregnerødvej 127, DK-3460 Birkerød, Denmark, Tel. +45 4582 4440, E-mail: jvlnyt@jvl.dk, Web: www.jvl.dk

See pictures in high resolution

JVL A/S Bregnerødvej 127 DK-3460 Birkerød Denmark

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk

Tel: +45 4582 4440 Fax: +45 4582 5550 E-mail: jvl@jvl.dk